U.S. Air Force General Proclaims Additive Manufacturing As A Massive Game Changer

Additive Manufacturing (DMLS) has been a rising trend that has the potential to revolutionize nearly everything we manufacture from human organs to mechanical components to firearm parts.

General Ellen Pawlikowski, Commander of the Air Force Material Command, compared the importance of additive manufacturing to other game-changing technologies like hypersonics, directed energy, and autonomy, stating,

“If you were to ask me what’s the fourth game changer, in my mind it’s additive manufacturing.”

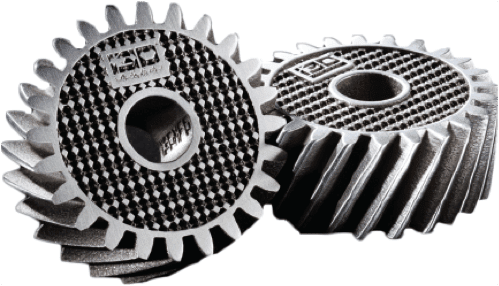

I3D MFG agrees with these statements as they have been at the forefront of this game-changing technology for nearly two years now, producing some of the most complex and revolutionary parts for their aerospace, firearms, heat exchanger and thruster clients

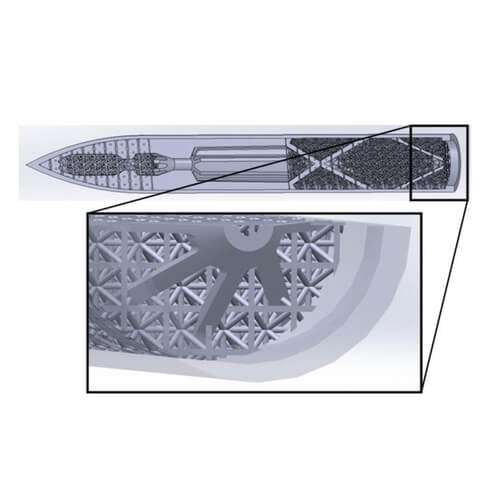

For the Air Force, these types of 3D metal parts, including flexible electronics, sensors, fuzes, energetics and warheads, help AFRL achieve the longer-term goal of using technologies like DMLS to rapidly prototype advanced capabilities for warfighters.

Dr. Amanda Schrand, principal investigator for FLEGOMAN at the AFRL/RW stated,

“We are maturing additive manufacturing to address technical challenges in fuze technology and ordnance sciences to increase the lethality of small weapons, and enable modular and flexible weapons. We also hope to decrease the time it takes to refresh critical components as well as decrease the cost to produce a weapon and its components. We are currently focusing on additively manufacturing survivable fuze electronics such as detonators, switches, capacitors and traces, leveraging the expertise of our colleagues at the AFRL Materials and Manufacturing Directorate, Sensors Directorate, Air Force Institute of Technology and Army Armament Research, Development and Engineering Center. Additionally, we are developing tailorable, lightweight, cellular warhead cases and structural reactive materials that offer strength and energy on demand. Finally, we are exploring ways to improve energetic materials by printing them rather than pouring them.”

I3D MFG, is able to use their experience and engineering to design, recommend, and produce advanced metal components using additive manufacturing (DMLS) in order to fuel the next-generation of 3D metal printing techniques.