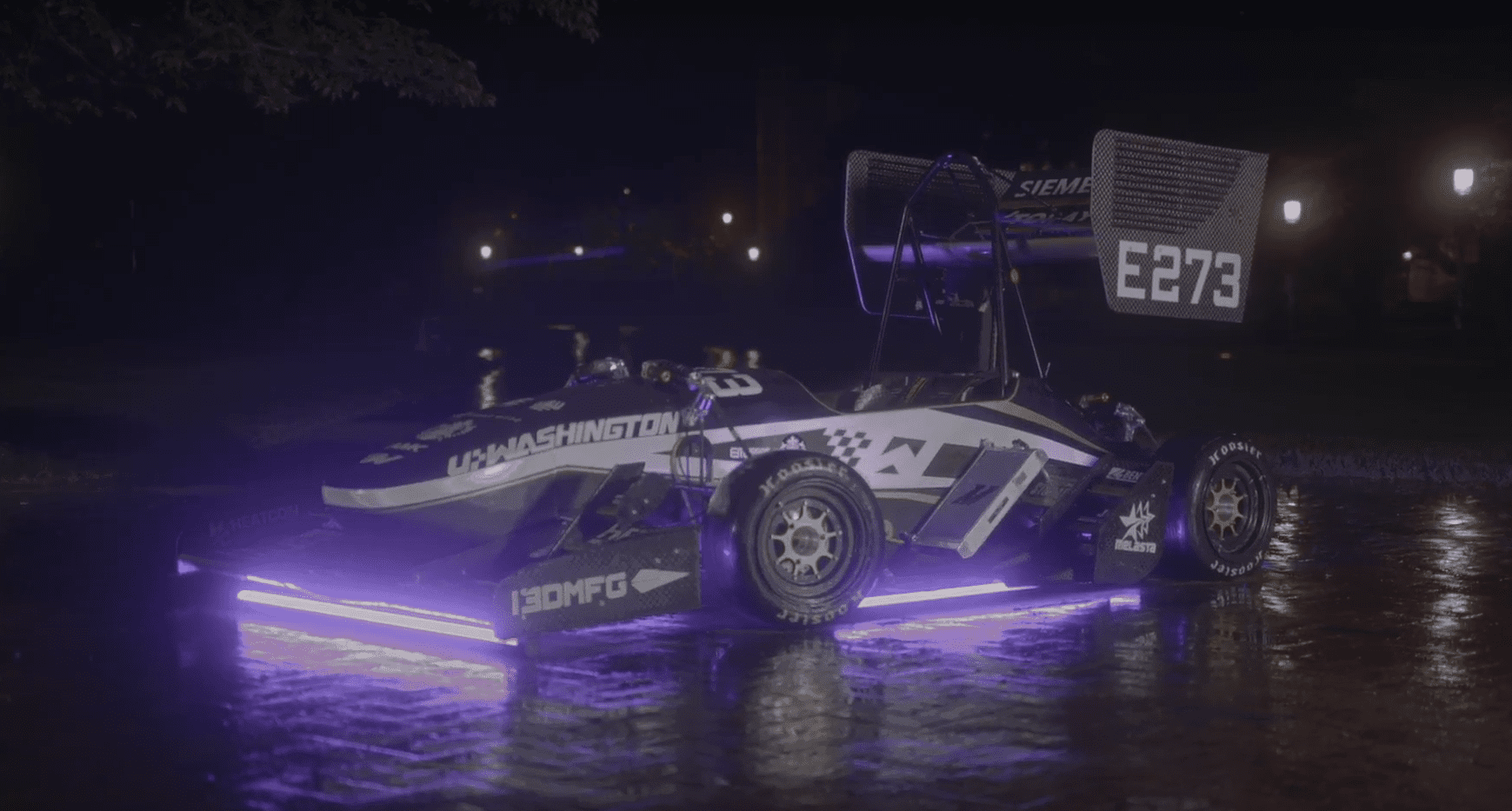

May 16, 2022 – University of Washington’s Formula Motorsports Team

I want you to know we have not forgotten about you guys and the help you’ve given us. Since I’m also the sponsorship lead, I did make sure you guys got one of the best spots on the car for your logo! Here’s a picture below!

Thank you again for everything and I hope we work together more in the future! The cooling jackets have been tested and all function well! It will be a highlight during the design competition in Michigan when we head there in July as it’s a testament to our foray into additive!

May 9, 2022 – Customer since 2016 – Feedback on M400.4 parts printed in Inconel 718

May 9, 2022 – Customer since 2016 – Feedback on M400.4 parts printed in Inconel 718

Thanks for the extra diligence on field calibration. The first set of jackets I’ve seen myself have looked great.

April 28, 2022 – Printed parts in AlSi10 and 6061, we had iterative builds to get here.

I just wanted to follow up with you regarding the parts you printed. We are just beginning testing so there are no results quite yet. However, we took some x-rays of the parts to observe the condition of the internal channels and they appeared to be clear of blockages and in good condition. This was exciting as achieving quality channel geometry is typically the most difficult part with printed PHPs. I thought you would like to know and maybe pass this along to your team.

Customer since 2019

I just wanted to follow up with you regarding the MIDS plates you printed. We are just beginning testing so there are no results quite yet. However, we took some x-rays of the parts to observe the condition of the internal channels and they appeared to be clear of blockages and in good condition. This was exciting as achieving quality channel geometry is typically the most difficult part with printed PHPs. I thought you would like to know and maybe pass this along to your team.

January 21, 2022

“I am a member of the Drivetrain subteam on the University of Washington’s Formula Motorsports team. We are a student team and our goal is to design, build, and compete with a fully electric racecar. Our design underwent a monumental change this year which prompted us to look into additive metal manufacturing to create a particularly complex part, our motor cooling jacket. After little to no luck speaking with some larger manufacturing companies, we found an excellent partner in i3dMFG. Not only has the team been cooperative from the very first phone call, they have assisted us on the printability of the design throughout the process, suggesting small changes while working with a team engineer. Over the course of this process, i3dMDG created six Aluminum Direct Metal Laser Sintered cooling jackets for our new drivetrain package. We are currently in the process of manufacturing our racecar and are excited to assemble our system with this part highlighted. As a team that has stuck to subtractive manufacturing, we could not have asked for a better partner to help us venture into the additive manufacturing realm. The knowledge and designs made this year will be essential to this year and future years. From everyone at UW Formula Motorsports, we’d like to give a huge thank you to our friends at i3dMFG for their support!” -Vishwa KN

January 20, 2022

I don’t know if you are involved with employee reviews. If not please forward to whoever is that person. I just wanted you to know from a customer that Stephanie is fantastic. She makes my job and oversight so much easier. She happily does anything we request and does it fast and correctly. If something is not right, its because of a subtier supplier that doesn’t follow our written and verbal directions. She’s totally transparent and keeps me in the loop on everything. We talk virtually every day and is fun to work with. She’s logistical and organizational goddess. We all need more co-workers like her. Dominick is doing fine job also and his role will be increasing more as we do more printing. Its been great working with I3D so far as we explore new materials on this program. Please let your team know of my satisfaction.

Russ Cochran, The Boeing Company, November, 2020

I just opened up the box to our shipment we had you complete. Very pleased by the work you have completed. The two boxes look great. I look forward to any future work.

Pacific Northwest National Labs (PNNL) ran independent tests on AlSi12 DMLS parts from i3DMFG and determined that the density of the parts we are printing is 2.62 g/cc …” that is virtually the same as the density of cast AlSi12, very impressive!”

I had contacted at least 6 different services to get this job done, but none could come close to your price/delivery combination. One of the services had a very slick automated web quoting system, and their price was actually very good (~15% cheaper), but the leadtime was too long ~3-4 weeks, and there was nobody to talk to. Also, another service could have done the job in the required schedule, but at twice the price. Then another wasn’t even able to quote the job within 1 week. The main difference with your service was because I had a direct single point of contact (Robbie) that was very responsive to all the questions and iterations of quotes; this made all the difference. We will be mailing the check today. Thank you again, and you will definitely be our top choice for future RP needs.”