What can be 3D printed? Talking Materials

What can be 3D printed? Talking Materials

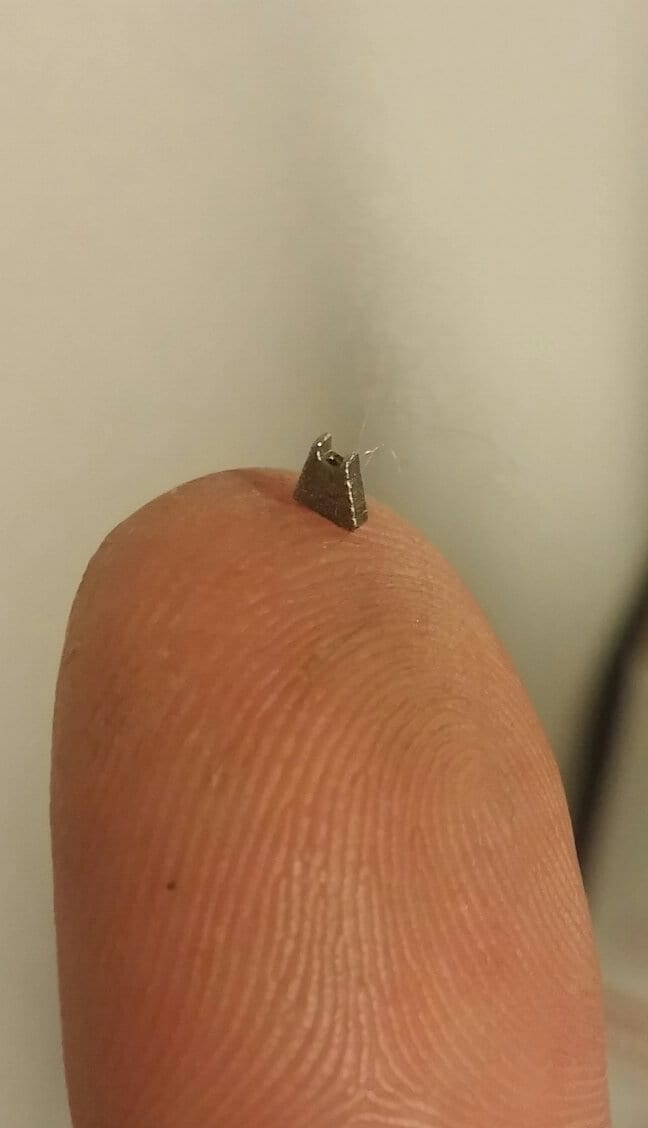

There are many options for metal materials in the world of 3D printing. The most common metals used to print parts are Aluminum, Titanium, Inconel, and Stainless Steel. Each of these metals hold unique properties that set them apart from one another. Depending on the desired use of the part, certain materials are more sought after for specific applications and performance vs others.

Aluminum is widely used in the Aerospace industry because of its lightweight material properties. Aluminum has a high strength-to-weight ratio, low density, and natural anti-corrosive properties meaning it doesn’t degrade due to oxidation. AlSi10 is i3D MFG’s most common aluminum powder and generates a high success rate in parts with thin walls and complicated geometries. Another option available is Al6061, which is a highly ductile and cost effective aluminum that prints more than 50% faster than AlSi10. For this reason, it’s becoming more popular in the AM industry for customers seeking faster build times.

Titanium is another popular choice for customers seeking high corrosion resistance with their parts. Similar to Aluminum, Titanium provides low weight and high strength making it an ideal material for Aerospace and Automotive applications. Titanium is commonly used as an alloying element with Aluminum or Steel to achieve specific properties in terms of ductility, strength, and hardness. Ti64 powder is well suited for projects requiring weight reduction and bio-compatibility. Ti64 typically hardens to 36-41 HRC after heat treatment.

Inconel comes from a family of high-performance alloys, known for its strength and resistance to thermal degradation. Because of this, Inconel alloys (such as IN625 and IN718) hold up when used in high temperature applications. Industries such as the Aerospace and Automotive industry use Inconels because they provide superior heat resistance with a typical heat treatment hardness of 40-47 HRC.

Similar to Inconel alloys, Haynes 282 is a super-alloy developed for high temperature structural applications and provides excellent resistance to strain-age cracking. Haynes 282 also has high ductility making it easy to fabricate and machine, because of this it is a popular material choice for the Aerospace and Automotive industry. Haynes 282 powder typically hardens to 20-32 HRC after heat treatment.

Stainless Steel is commonly sought out for projects that require high resistance to heat and corrosion. Our stainless steel powders are medical grade and typically harden to 40-45 HRC after heat treatment. Due to its characteristics, Stainless Steel is a particularly good choice for parts requiring high strength and hardness. Stainless steel parts can be machined, welded, polished, and coated making them ideal for corrosion resistant applications.

Whatever your desired application is, i3D can help assess your needs and provide suggestions for materials that will cause your project to excel. From prototypes to production ready parts, we’re happy to navigate customers through our selection of high-performance metals to help pick the right material for any given project.