We’re excited to announce that i3D Manufacturing has officially joined the BTX Precision family, bringing together our additive expertise with BTX’s industry-leading manufacturing platform.

We combine world‑class quality, industrial‑scale capacity, and deep additive‑engineering.

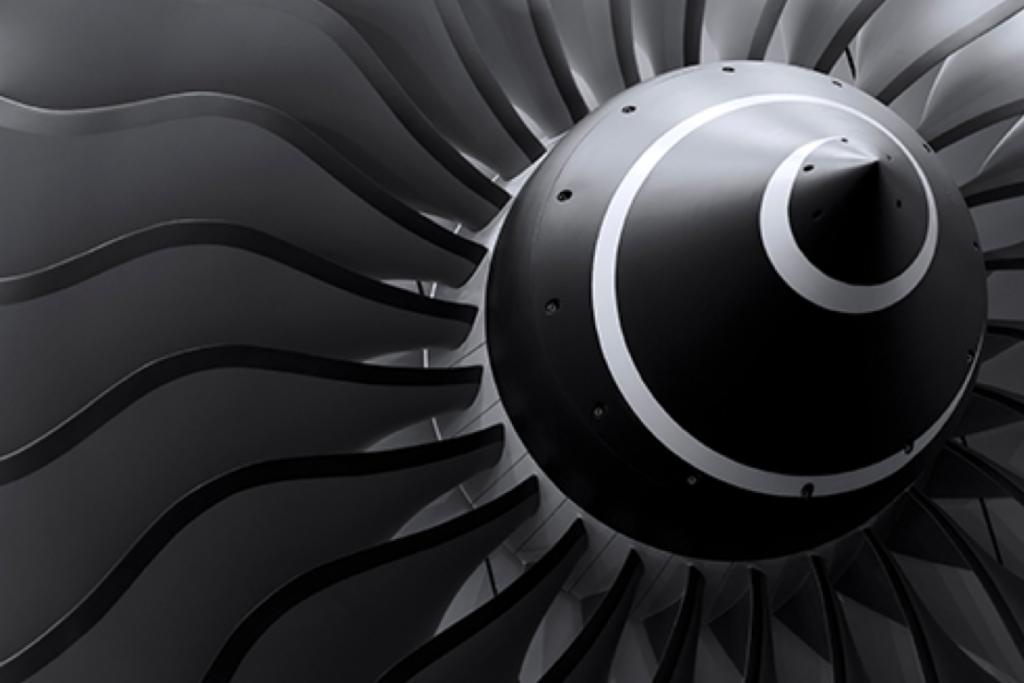

Our mission is to revolutionize manufacturing by delivering high-performance, precision-engineered metal additive solutions that empower innovation across aerospace, defense, and energy industries.

Certified Confidence

Our facilities are certified to AS9100D, compliant with CMMC standards, and hold ITAR registration plus FFL licensing at both sites. These rigorous credentials ensure your project meets the strictest security, compliance, and traceability requirements.

Volume-Ready Production

With 30 cutting‑edge EOS DMLS® machines—and room to expand—our capacity flexes to your needs. From single‑part prototypes to large‑volume production runs, we deliver on schedule without compromising quality.

Proven Expertise

Our engineering and design teams have the “been there, done it” experience across complex additive projects. You gain a partner who understands how to optimize geometry, materials, and processes for maximum performance—and who’s solved the toughest manufacturing challenges.

We rely on EOS 3D printing machines for their unmatched precision, and reliability.

- 3D Manufacturing of metal, fully functional, production parts

- Iteration and prototyping reduced from months to weeks and days

- Part consolidation with no need for tooling or molds

- Reduce weight by 70% with latticed & honeycomb geometries

- 16 stocked powders, 22+ parameters available

- Other EOS Machine platforms include: EOS M400.4, M300.4 & M290

3D Additive Metal Powders

i3DMFG™ is one of the few 3D manufacturers in the US that has expertise in a wide variety of metals, including aluminum, copper, titanium, Steel, Inconel®, Haynes®, Monel®, Stainless Steel and custom metal powder applications. Experts in 3D design and component optimization, our engineers help our customers achieve competitive advantage in design and proprietary advancements.

- Aluminum (AlSi10)

- Super Nickle Alloys

- Titanium (Ti64)

- Stainless Steels

- Marging Steel (MS1)

- Copper

Case Studies

See how advanced 3D printing technology has helped companies across solve complex challenges.

Advancing UAV Performance with DMLS Metal 3D Printing

As UAVs become more sophisticated, manufacturers face increasing pressure to deliver lighter, more efficient, and highly optimized components without compromising strength or reliability. Traditional manufacturing methods often limit the complexity and integration of UAV parts, making it difficult to meet the evolving needs of defense, aerospace, and commercial drone markets.

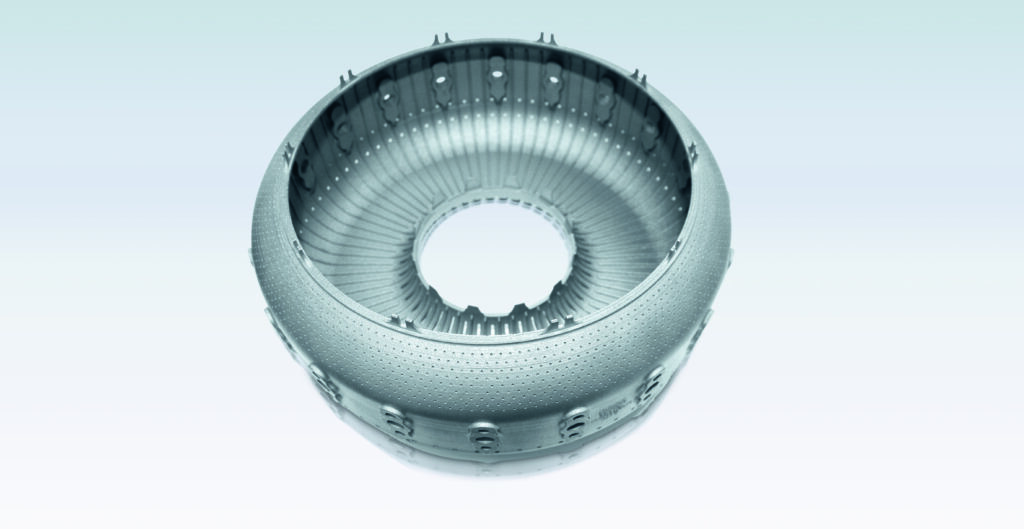

Advancing Thruster and Rocket Component Manufacturing with DMLS

Thruster and rocket applications demand components that can withstand extreme environments — including high temperatures, pressure variations, and corrosive conditions — all while maintaining performance, reliability, and tight tolerances. i3D MFG® leverages Direct Metal Laser Sintering (DMLS) to meet these challenges with precision-manufactured, fully dense metal parts optimized for aerospace propulsion systems.

Advancing Heat Sink Design Through DMLS

As electronic components continue to increase in power density, the need for effective passive cooling systems becomes more critical. Natural convection — a quiet, low-cost, and low-interference cooling method — often struggles to meet the demands of medium to high power outputs. This case study explores how Direct Metal Laser Sintering (DMLS), an advanced additive manufacturing technology, was used to redesign a traditional extruded LED heat sink to significantly improve thermal performance.