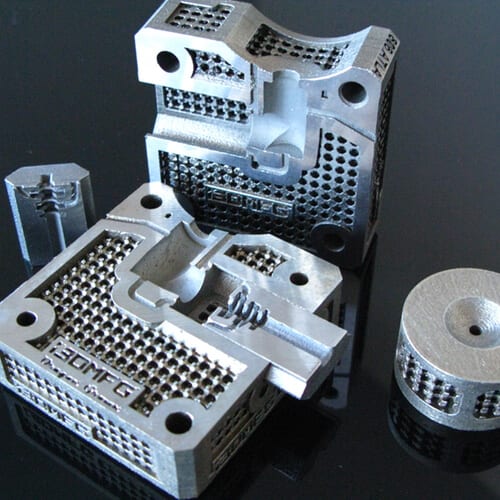

Direct Metal Laser Solidification (DMLS®) is a 3D printing process that revolutionizes mold tool design and production. 3D CAD models drive the machine to fuse micro-layers of powder together using 400W lasers on 20 to 60 micron layers of metal powder, creating a nearly 100% dense, fully functional production mold tool. DMLS® can “print” conformal cooling lines, lattice geometries, and complex core/cavity designs that are too costly or simply impossible to traditionally manufacture. This opens up unlimited options for engineers to incorporate internal channels, curved features, cooling and heating efficiencies, varied layers throughout a single mold, and flexible interchangeable mold designs.

i3DMFG™ can print mold core/cavities in days, giving end-use customers competitive advantages in time-to-market, product development, and small batch production. Our aluminum and tool steel, and stainless steel mold tools can be post-processed in all of the same ways as cast or machined parts, from polishing to welding to anodization.