Blue Light 3D Scanner

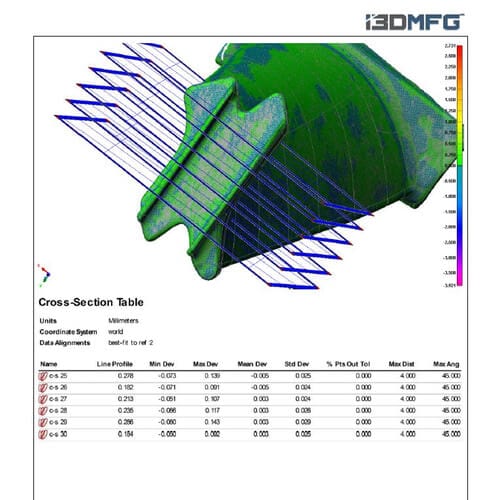

i3DMFG™’s 3D scanner performs surface height measurements of parts using Coherence Scanning Interferometry (CSI) using spectrally-broadband (‘blue-light’) illumination. Various scanning interferometer configurations may be used to measure macroscopic objects with surface profiles measuring in the centimeter range, to microscopic parts with surface profiles measuring in the micrometer range (µm). i3DMFG™ uses its 3D scanner to inspect each part to insure specification conformance.

3D scanning is also a useful tool for FEA analysis, reverse engineering, obsolete part re-creation, and quality assurance measures. Our Polyworks software platform combined with blue-light scan technology creates a powerful 3D tool for file creation, part inspection, quality assurance reporting, and one-off part production.