Wire Electronic Discharge Machining (Wire EDM)

Electrical Discharge Machining (EDM), also called spark machining, spark eroding, or wire erosion, is a precision manufacturing process through which, a desired shape is cut to held tolerances of up to +/- .001 mm using electrical discharges across a fine wire. i3DMFG™ utilizes the precise CUT 30P’s strict tolerances to remove parts from its DMLS® build plates.

Many of our customers have found that there are less complex, but high tolerance parts that are well-suited to production on the Wire EDM. With minimal set-up time for intricate cutting patterns, the CUT 30P is a perfect complimentary manufacturing process.

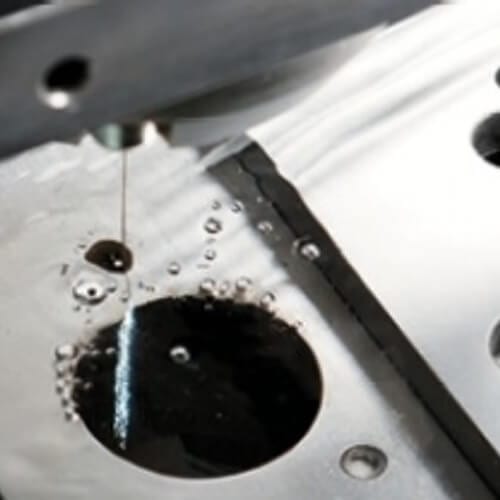

Material is removed from the base stock through a series of rapidly recurring current discharges between two electrodes (the ‘tool’ electrode and the ‘work-piece’ electrode), separated by a dielectric liquid and subject to electric voltage.

Key Statistics:

- Wire diameters from 0.15mm to 0.30mm

- Accuracy of up to .001mm

- Conductive materials to any hardness (i.e. steel or titanium)

- Surface finish as fine as 5 microns