Precision Turning After 3D Metal Printing

Once a metal part is produced using additive manufacturing, it often requires post-processing to meet tight dimensional tolerances and surface finish specifications.

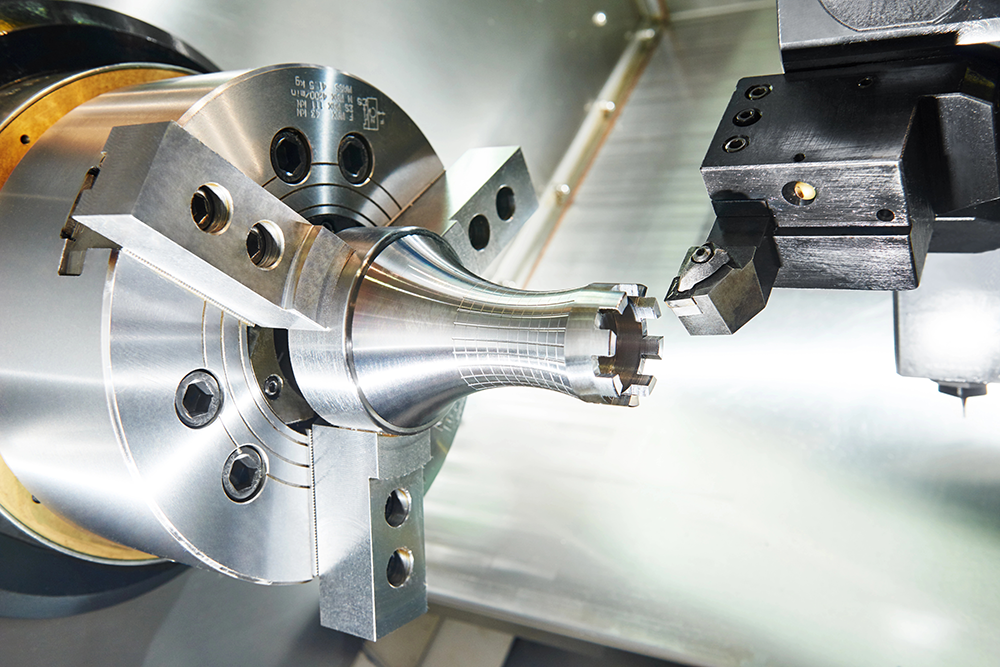

Turning is a critical step in this process. By mounting the printed part onto a lathe, cylindrical features such as shafts, threads, and holes can be machined with exceptional accuracy. Turning not only enhances the part’s geometry but also removes surface roughness inherent to the 3D printing process. This step is especially important for functional surfaces that demand smooth finishes or precise fits, such as bearing seats or sealing surfaces.

With CNC turning, we ensure each part meets strict quality and performance requirements, turning complex printed geometries into ready-to-use components.

EDM Machining for Complex Geometries

3D metal printing allows the creation of intricate internal structures and fine details that are difficult or impossible with traditional subtractive methods. However, post-print finishing is often necessary to achieve the final part’s required precision—especially in hard-to-reach areas. That’s where EDM (Electrical Discharge Machining) comes in.

EDM uses controlled electrical sparks to erode material with extreme accuracy, making it ideal for machining hardened metals and tight-tolerance features. It excels at refining internal channels, sharp corners, and deep cavities in printed parts without applying mechanical force. EDM is a key finishing process that brings the precision and complexity of 3D printed parts to life, enabling true end-use functionality.