Advanced Metal 3D Printing with DMLS® Technology

At i3D MFG®, we harness cutting-edge Direct Metal Laser Solidification (DMLS®) technology to deliver high-performance, production-grade metal parts that meet the most demanding requirements. Our fleet of DMLS systems enables unparalleled precision, design freedom, and efficiency for industries where performance, speed, and complexity matter.

Core Capabilities

Our core capabilities span the full spectrum of metal additive manufacturing— from initial design optimization and rapid prototyping through precision DMLS® printing and comprehensive post processing. Backed by AS9100D-certified quality systems and in-house DFAM expertise, we deliver end-to-end solutions that accelerate time-to-market and ensure consistent, high-performance results.

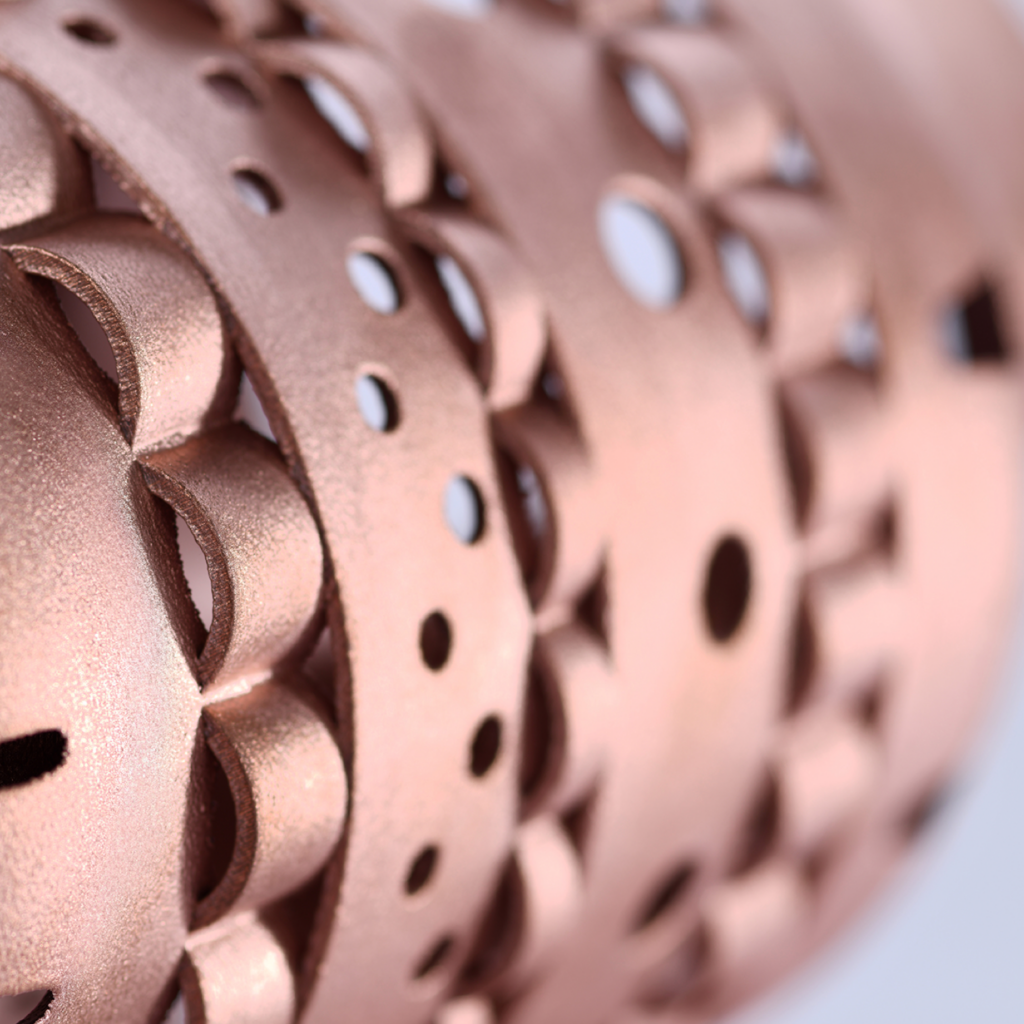

Complex Geometries, No Compromises

DMLS eliminates the design constraints of traditional machining and casting. We manufacture fully functional metal components with complex internal channels, free-form surfaces, lattice structures, honeycombs, and conformal cooling pathways—no tooling, CNC programming, or post-fixture setup required.

Production-Ready Precision

From prototypes to production, we deliver repeatable, high-quality results with:

- Feature resolution down to 0.015″ (0.38 mm)

- Wall thickness as low as 0.012″ (0.3 mm)

- Layer thickness options of 20 or 40 microns

- Tolerances of ±0.005″ on first articles, ±0.002″ thereafter

Build Volumes for Every Need

Our equipment supports multiple build sizes to fit various project scopes—from intricate components to large-format parts:

- Small to medium: ~228 × 228 × 190 mm to 250 x 250 × 300 mm

- Large-format: up to 400 × 400 × 400 mm

This scalability allows clients to iterate quickly, consolidate assemblies, or scale production efficiently.

Lightweighting & Structural Optimization

We help customers reduce component weight by up to 70% using latticed, honeycombed, and topology optimized designs—all without compromising strength or function.

Rapid Turnaround & Seamless File Support

Our streamlined workflow supports rapid prototyping and production, with lead times as short as hours or days. We work directly with Solidworks, .STEP, and raw CAD files, enabling fast, tool-free manufacturing cycles.

High-Performance Materials in Stock

We support a wide range of in-stock metals, including:

Titanium

Aluminum

Inconel

Copper

Stainless Steel

Maraging (Tool) Steel

Hastelloy X

Haynes 214, 242, 282

Applications Across Industries

Whether it’s a lightweight aerospace bracket, a conformally cooled mold insert, or a heat resistant engine component, our DMLS capabilities deliver performance, consistency, and innovation at every layer.

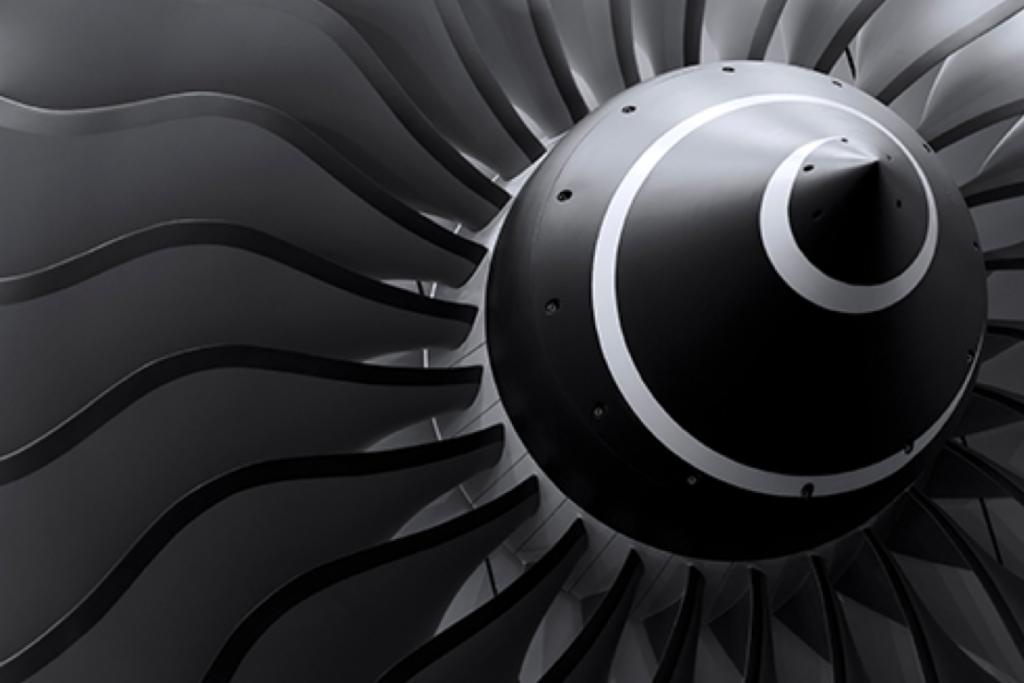

Aerospace

By harnessing topology optimization and aerospace-grade alloys, we deliver components with superior performance and reduced lead times—empowering faster iteration and safer flight.

Defense

Our metal 3D printing solutions deliver ruggedized enclosures, precision mounts, and mission-critical hardware with full ITAR compliance. With AS9100D-certified processes and FFL licensing, we ensure traceability, security, and unwavering reliability for defense applications.

Energy

Our additive-manufactured valve bodies, heat exchangers, and custom manifolds use nickel and stainless-steel alloys to deliver long service life, optimized fluid dynamics, and on-demand production scalability.

Space

We print ultra-lightweight structures and high-temperature alloys—designed for the vacuum, thermal cycling, and radiation of spaceflight. Our precision builds enable complex geometries for propulsion, thermal control, and structural systems on satellites and launch vehicles.

Recreation

Lightweight, durable parts—from topology-optimized bicycle components to corrosion-resistant water-sport hardware—enabling rapid R&D, small-batch runs, and one-off customizations that set your products apart.

Medical

Patient safety drives every step of our medical applications. From biocompatible titanium implants to custom surgical guides, we produce parts with fine detail, smooth finishes, and exacting tolerances.

Capability Constraints

At i3D, we help customers navigate the unique constraints of DMLS by providing the insight needed to make informed design decisions. By understanding these limitations early, we empower our partners to unlock the full potential of additive manufacturing.

1. Support Structures and Build Orientation

- Complex geometries often require support structures during printing, especially for overhangs greater than ~45°.

- Support removal can impact surface finish and increase post-processing time.

- As-printed surfaces typically have a rough finish (Ra 8–20 µm), depending on the material and build parameters.

- Additional post-processing such as machining, polishing, or shot peening is often required to meet tight surface specifications.

2. Part Size Limitations

- Build volumes are restricted by the printer model (e.g., max ~400 × 400 × 400 mm)

- Larger parts may require segmentation and assembly after printing.

3. Material Availability

- DMLS supports a wide range of metals, but not all alloys can be printed.

- Material properties may vary from wrought equivalents, and custom alloy qualification can be time-consuming and costly.

4. Thermal Stress and Warping

- Rapid heating and cooling can cause residual stresses, distortion, or cracking—especially in thin-walled or large parts.

- Proper design for additive manufacturing (DfAM) and simulation helps mitigate these risks.

5. Cost Considerations

- While DMLS reduces tooling and enables complex parts, the cost per part may be higher than traditional manufacturing for large production volumes.

- Best suited for low- to mid-volume production, high-complexity parts, or parts where performance justifies the cost.

6. Powder Handling and Safety

- Metal powders require controlled handling environments due to flammability and inhalation risks.

- i3D follows strict safety and quality protocols for powder storage, reuse, and disposal.