From Concept to Component:

Our Proven Project Workflow

At i3D, we transform your ideas into high-performance metal parts through a streamlined, end-to-end project development process. Whether you’re developing a new product or optimizing an existing one, our four-phase approach ensures quality, repeatability, and speed to market—without compromising precision or performance.

1. Proof of Concept: Validating Ideas with Speed and Agility

Every successful project starts with a strong foundation. During the Proof of Concept phase, we collaborate closely with your team to evaluate feasibility, identify key performance goals, and test initial designs using metal additive manufacturing. This phase allows for rapid iterations and performance assessments, enabling data-driven decisions before committing to full-scale production. It’s the ideal stage to explore innovation with minimal risk and maximum flexibility.

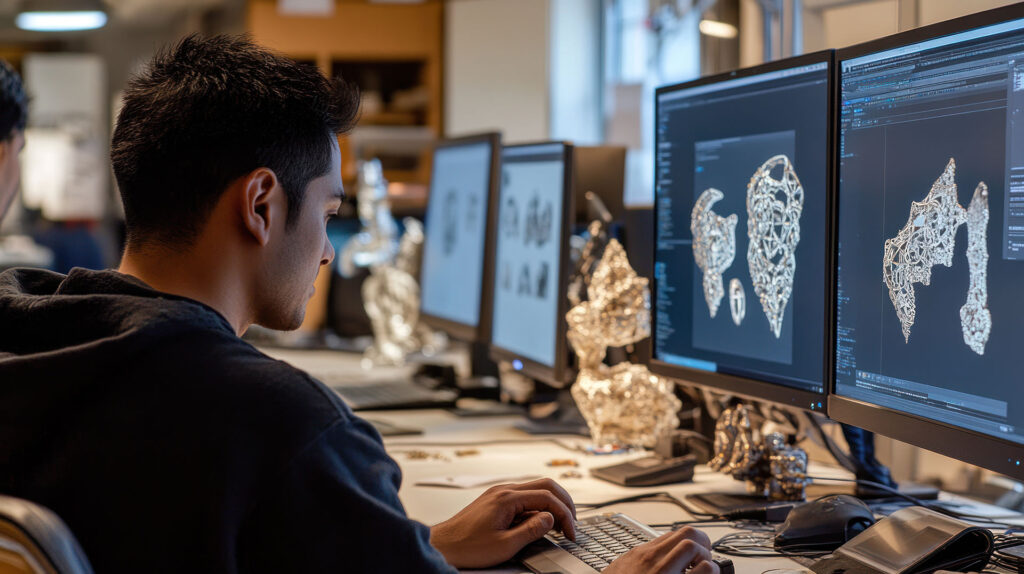

2. Design for Manufacturing (DFM) Optimizing Designs for Printability and Performance

Once your concept is proven, we move into Design for Manufacturing. Here, our engineering team applies additive manufacturing expertise to refine your part for optimal printability, strength, cost-efficiency, and downstream processes. This includes evaluating support structures, orientation, and tolerance strategies—all tailored to meet your functional and regulatory requirements. DFM ensures a smooth transition from prototype to production while minimizing waste and maximizing repeatability.

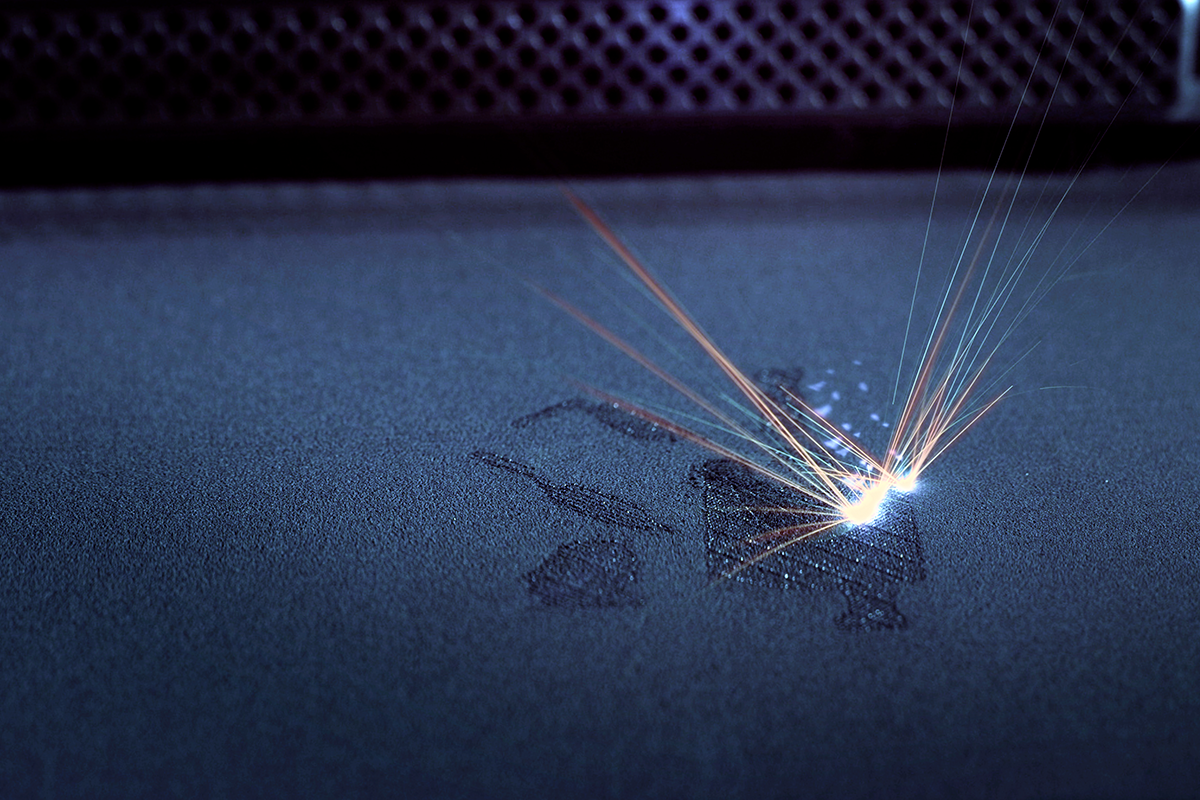

3. Production Precision Printing at Scale

With a finalized design in place, we initiate full-scale metal 3D printing using our advanced industrial AM systems. Our in-house team monitors each build to ensure consistent quality, dimensional accuracy, and mechanical performance. Whether you’re producing a limited batch or scaling up for higher volumes, we deliver reliable, repeatable parts manufactured to the highest standards—on time, every time.

4. Post-Processing Finishing

Metal additive parts often require post-processing to meet tight tolerances, surface finishes, or mechanical properties. i3D offers a complete suite of finishing services including turning, EDM, and surface cleaning. Each part is inspected and finalized to your exact specifications, ensuring it’s ready for immediate use in your assembly, test, or deployment environment.