No. But something else can. 3D Printed parts.

Engineers have known that 3D printed rocket parts can save money and spark new design possibilities but no one had really tested 3D printed rocket parts critical to engine combustion in a hot-fire environment.

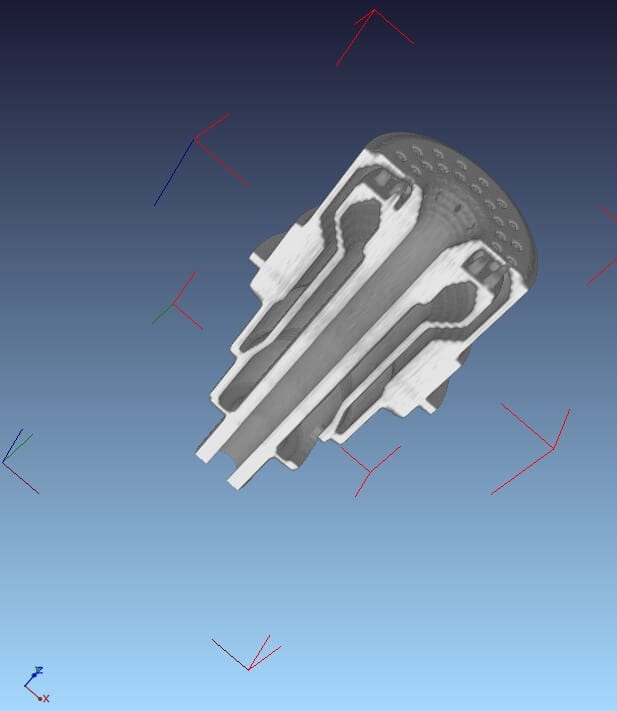

NASA engineers have recently put 3D printed engine parts to the test and then took it further. They were able to compare their performance to parts made with traditional manufacturing (using welds and multiple parts). In order to test, they built two sub scale injectors with a specialized 3D printer and performed 11 main stage hot-fire tests.

“We saw no difference in performance of the 3-D printed injectors compared to the traditionally manufactured injectors,” said Sandra Elam Greene, the propulsion engineer who oversaw the tests and inspected the components afterward. “Two separate 3-D printed injectors operated beautifully during all hot-fire tests.”

The NASA team was so impressed with the 3D printed parts that they will continue to put them directly in the line of fire. In fact, they recommend additive manufacturing because it has the potential to reduce the time and cost associated with making complex parts by an order of magnitude.

A J-2X engine exhaust port cover made at the Marshall Center became the first 3-D printed part tested during a full-scale engine hot-fire test at NASA’s Stennis Center. Marshall materials engineers are currently making a baffle critical for pogo vibration mitigation; it will be tested at Marshall and Stennis and is a potential candidate for the first SLS mission in 2017. Marshall engineers are finishing up ground tests with Made in Space, a Moffett Field, California company working with NASA to develop and test a 3-D printer that will build tools on the International Space Station next year. NASA’s Johnson Space Center in Houston is even exploring printing food in space.

Here is a video of the test firing: